Getting colors to appear exactly as intended can feel like a big challenge, especially when dealing with specific shades like Pantone 300C. This particular blue is a staple for many brands, yet making sure it looks the same across different materials and screens often causes a lot of head-scratching. We are talking about the difference between what you see on your computer and what comes off the printer, or how a color looks on a sign compared to a race car. It is a common problem, so you are not alone in facing these kinds of color matching puzzles.

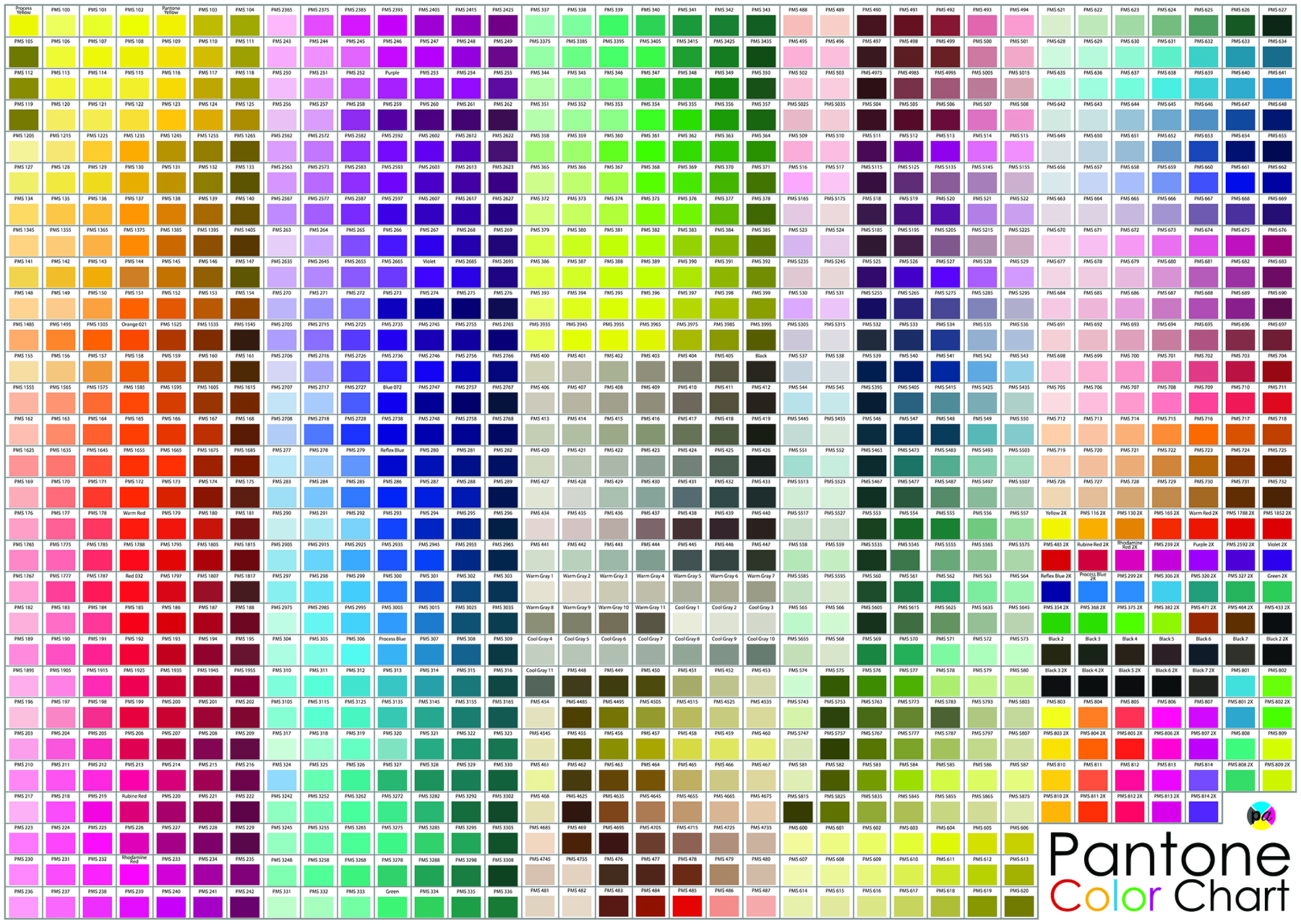

Many folks, you know, struggle with how to accurately reproduce these precise colors. Maybe you have tried printing a Pantone chart from Illustrator, only to find the results on your Epson S80600 printer were not quite right. Or perhaps you have heard about Pantone Connect and wondered why it became a thing, with claims that Adobe did not update their swatch books. These issues are very real for anyone working with design and production, trying to keep color consistent across everything. So, we will look into how to get Pantone 300C right, every time.

This discussion will cover what Pantone 300C means for your projects, how to approach printing it accurately, and some common problems people run into. We will also touch on how to handle color conversions and the importance of having good reference materials. It is all about making your color work easier and more predictable, ensuring that blue always looks just as it should, for instance.

Table of Contents

- Understanding Pantone 300C: What It Is and Why It Matters

- The Challenge of Printing Pantone Colors

- Converting and Matching Pantone 300C

- Best Practices for Color Accuracy

- Frequently Asked Questions About Pantone 300C

- Conclusion

Understanding Pantone 300C: What It Is and Why It Matters

Pantone 300C is a specific shade of blue within the Pantone Matching System. It is a standardized color, meaning it should look the same no matter where it is used, provided the right processes are followed. This standardization is incredibly important for brand consistency, so you know a logo's blue will be the same whether it is on a business card or a billboard. It helps ensure that everyone involved in a project, from designers to printers, is speaking the same color language, in a way.

For designers, choosing a Pantone color means selecting a shade that has a very precise recipe. This recipe helps ensure that when the color is mixed, it comes out exactly as intended. It takes away much of the guesswork that can happen with other color systems, which is pretty helpful. This is why customers often ask for their materials to match a specific PMS color, for instance.

The "C" in Pantone 300C means "coated." This refers to the type of paper stock the color is meant for. Coated paper has a smooth finish that can make colors appear brighter and more vibrant. There is also an "U" for uncoated, which looks a bit different because the ink soaks into the paper more. Knowing this distinction is important for getting the right look, so you know what to expect.

Spot Color Magic

Pantone colors are often called spot colors. This means they are mixed as a unique ink, rather than being created by combining dots of cyan, magenta, yellow, and black (CMYK). Think of it like baking a cake with a pre-mixed frosting color instead of trying to mix food dyes yourself. This method provides a much more consistent and often more vibrant color, you know.

Spot colors are printed as distinct layers in offset printing or screen printing. They are typically mixed manually using about 15 base colors. This process allows for a level of color accuracy that is quite hard to achieve with CMYK alone. It is how you get that perfect brand blue to appear the same across different items, so it is a big deal for quality.

This approach is especially useful for things like company logos or specific brand elements where color consistency is really important. When a customer needs decals for a race car, for example, they want that vinyl to match their car exactly. Spot colors help achieve that kind of precision, as a matter of fact.

Digital Versus Physical Color

A big challenge with Pantone 300C, or any Pantone color, is how it looks on a screen compared to how it looks in print. Screens use light (RGB) to create colors, while printers use ink (CMYK or spot inks). These are fundamentally different ways of making color, which means there will always be some variation. It is a bit like comparing apples and oranges, so to speak.

Many people try to pull a Pantone chart off Google Images and print it. While this can give you a general idea, it is not a reliable way to get an accurate color reference. Your monitor's calibration, your printer's settings, and the paper you use all play a part in how that printed chart looks. It is just not the same as a professionally printed Pantone book, you know.

This difference is why many designers and printers rely on physical Pantone swatch books. These books show the actual ink on paper, giving a true representation of the color. They are the standard for color communication, helping to bridge that gap between the digital design and the final printed piece. It is really the best way to ensure color accuracy, honestly.

The Challenge of Printing Pantone Colors

Printing Pantone colors accurately can be a complex task. It is not always as simple as hitting "print" and expecting perfection. There are many factors that influence the final output, from the software you use to the type of printer and the materials. This is where many of the real-world problems start to show up, you know, when you are trying to get things just right.

For instance, some printers might produce colors that are darker than expected, even when you have matched them to CMYK values. This can happen with decals for a race car, where the exact shade is very important. Understanding these potential issues is the first step to overcoming them, so you can plan accordingly.

The goal is to get the physical output to match the desired Pantone shade as closely as possible. This often involves careful calibration, testing, and sometimes, a bit of trial and error. It is a process that takes some patience, but it pays off in the end with consistent color, obviously.

Printing Your Own Charts

Many folks wonder if there is an easy way to print a Pantone color chart out of Illustrator. While you can print a chart, getting it to be truly accurate is another story. The problem is that your desktop printer, even a good one like an Epson S80600, might not reproduce the spot colors perfectly. It is more likely to simulate them using CMYK inks, which can look different, you know.

Some people have gone to great lengths to build their own numbered Pantone charts from solid coated colors. This takes a lot of effort, but it can be useful for specific applications, like printing on various materials to see how the color behaves. It is a testament to how important accurate physical references are, actually.

If you do print your own charts, treat them as a rough guide rather than an exact standard. They can be helpful for internal reference or for making a quick swatch book for your lobby. But for precise client work, a professionally produced Pantone color bridge book is almost always the better option, so you know the color is correct.

Software and Swatch Books

The relationship between design software and Pantone swatch books has been a point of discussion. Pantone claims they were forced to launch their Connect service because Adobe did not update their versions of Pantone's swatch books. This situation highlights a real challenge for designers: ensuring their digital color libraries are current and accurate. It is a constant back-and-forth, in a way.

When you are working in software like Illustrator or Flexi19, you might use built-in Pantone color tables. However, finding a specific color in these huge digital charts can be a bit of a task. It is easy to get lost, and sometimes the digital representation might not perfectly reflect the physical swatch. This is why having both digital and physical references is pretty important.

The way digital Pantone libraries are managed can affect how colors are rendered on screen and how they are interpreted by your printer. If the software's color values are not in compliance with Pantone, Inc.'s standards, then your output might not match the desired PMS color. This is a key reason for color discrepancies, so it is worth paying attention to.

Printer Differences

Different printers handle colors in their own ways. An Epson S80600, for example, might have different color profiles than another large format printer. This means the same CMYK values or even a simulated spot color can appear different from one machine to another. It is a common source of frustration for those trying to get consistent results, you know.

When you are printing decals or dimensional letters, and a customer needs a precise PMS match, your printer's capabilities become very important. If your printer is printing darker than the CMYK match you made, it suggests a calibration issue or a difference in how the printer interprets color data. This needs to be addressed for accurate output, as a matter of fact.

For true spot color printing, especially in offset or screen printing, the inks are mixed manually to the exact Pantone formula. This bypasses the CMYK conversion issues that digital printers face. It is why, for exact color requirements, many prefer traditional printing methods or specialized printers that can handle spot inks. It offers a level of control that is quite high, honestly.

Converting and Matching Pantone 300C

Sometimes, you need to translate Pantone 300C into another color system or match it to an existing product. This is where color conversion and matching become important. It is not always a straightforward process, but there are ways to approach it that give you the best chance of success. It is all about finding the closest possible match, you know.

For example, you might have a customer who needs their product to match a specific PMS color, but your printer only uses CMYK. Or perhaps you are trying to match a paint color to a Pantone shade. These situations require careful consideration and the right tools. It is a common scenario in the world of design and production, so you are likely to encounter it.

Understanding the limitations of different color systems is key. Not every Pantone color can be perfectly replicated in CMYK, for instance. Some colors are outside the CMYK gamut, meaning they are too vibrant or too specific to be made by combining those four inks. This is where the challenge really comes in, obviously.

Sherwin Williams and Other Conversions

A common question is whether there is a chart that converts Sherwin Williams paint numbers to Pantone numbers. While direct, official conversion charts might be hard to come by, there are often unofficial resources or tools that can help. These tools usually provide the closest visual match, but it is important to remember that paint colors and ink colors are formulated differently. It is not always a one-to-one swap, you know.

For these kinds of conversions, it is often best to use a physical sample of the paint or material and compare it directly to a Pantone swatch book. This visual comparison is often more reliable than relying solely on digital conversions. It helps account for how light interacts with different surfaces, which can change how a color appears, as a matter of fact.

Similarly, if you are trying to find a Roland color chart reference number for a PMS code, you might look for online databases or specialized software. Some websites, like RALcolor.com for RAL colors, exist for other systems, and similar resources might be available for specific printer brands. These can be helpful starting points, so it is worth looking around.

CMYK Approximations

When you cannot print with a spot Pantone ink, the next best thing is to use a CMYK approximation. This means finding the combination of cyan, magenta, yellow, and black inks that most closely resembles Pantone 300C. Pantone provides CMYK values for their colors in their bridge books, which show how the spot color looks next to its CMYK equivalent. This is a very useful tool, you know.

However, as mentioned, CMYK might not perfectly match the vibrant or unique qualities of a spot color. You might find that your printer prints the CMYK version darker than expected, as some have experienced with race car decals. This requires adjustments to your print settings or color profiles to compensate. It is a common issue that needs a bit of fine-tuning, honestly.

When working with supplied artwork that uses Pantone colors, especially if it is an EPS file, you generally need to maintain those exact Pantone specifications for printing. Photoshop files, however, often rely on CMYK or RGB. Learning how to manage these different file types and their color spaces is important for getting accurate results. It is a key skill for anyone in this field, so it is worth developing.

Best Practices for Color Accuracy

Achieving consistent color, especially with a specific shade like Pantone 300C, comes down to following some good practices. It is about setting yourself up for success from the start and having the right tools and knowledge. These practices can help reduce frustration and improve the quality of your final products, you know.

The goal is to minimize discrepancies between what you design and what you produce. This involves a combination of using reliable references, understanding your equipment, and communicating clearly about color requirements. It is a continuous effort, but it pays off in the long run, as a matter of fact.

Remember that color is influenced by many factors, including lighting, material, and viewing conditions. Taking these into account can help you make more informed decisions about your color choices and production methods. It is a holistic approach to color management, obviously.

Using Physical References

The most reliable way to ensure color accuracy is to use physical Pantone swatch books. These books are printed with actual Pantone inks on specific paper stocks, giving you a true representation of the color. They are the industry standard for color communication, and they are pretty essential. For example, if you do not have a Pantone book, it is much harder to verify a PMS code/number.

A Pantone color bridge book is particularly useful because it shows both the spot color and its closest CMYK equivalent. This helps you understand how a specific Pantone color will translate if it has to be printed using CMYK. It is a valuable tool for making informed decisions about color reproduction, so it is worth having.

When a customer requires a specific Pantone color, you should always refer to a physical book to confirm the shade. Relying on digital images alone, even those pulled from Google, can lead to significant color mismatches. It is just not precise enough for professional work, you know.

Working with Design Files

When you get supplied artwork from customers, it often comes with Pantone colors because that is the industry standard. It is important to handle these files correctly to maintain color integrity. If the artwork is in an EPS file, for example, it is usually best to keep the Pantone spot colors intact for printing, especially if you are using a process that supports them. This ensures the color is precisely reproduced, honestly.

If you are working with software like Flexi19, getting used to its built-in Pantone color tables is important. However, sometimes finding a specific color in these large digital charts can be a bit tricky. Knowing how to navigate these tables and confirm the correct Pantone values is a skill that saves time and prevents errors. It is about efficiency and accuracy, in a way.

Always ensure your design software is using the most up-to-date Pantone libraries. This helps prevent issues where the software's interpretation of a color differs from the official Pantone standard. Staying current with software updates and color profiles is a simple step that can prevent many headaches, you know.

Troubleshooting Common Issues

If your printer is printing colors darker than expected, or if dimensional letters are not matching the PMS color, there are a few things to check. First, verify your printer's calibration. An uncalibrated printer can produce inconsistent results. This is a common culprit for color shifts, so it is a good place to start.

Next, check the color profiles being used in your design software and your printer driver. These profiles tell the software and printer how to interpret color data. Mismatched or incorrect profiles can lead to significant color differences. Ensuring they are consistent is a key step, for instance.

Finally, consider the material you are printing on. Different materials absorb ink differently, which affects the final color appearance. A vinyl decal might look different from a dimensional letter, even if printed with the same ink. Testing on the actual material is often the best way to predict the outcome, as a matter of fact.

Frequently Asked Questions About Pantone 300C

Many people have questions about Pantone 300C and color matching in general. Here are some common inquiries we hear.

What is Pantone 300C?

Pantone 300C is a specific, standardized shade of blue within the Pantone Matching System. The "C" means it is formulated for coated paper. It is a spot color, meaning it is mixed as a unique ink rather than being made from CMYK dots, which helps ensure very consistent and precise color reproduction, you know. It is a popular choice for brands needing a clear, vibrant blue.

How do I print a Pantone color chart accurately?

Printing a Pantone color chart from your desktop printer, like an Epson S80600, will likely give you a CMYK simulation, not a true spot color representation. For accurate charts, it is best to use a professionally produced Pantone color bridge book. These books show the actual ink on paper and are the industry standard for color reference, so they are really reliable. You can make your own for rough reference, but they won't be exact, honestly.

Why do my Pantone colors look different on screen versus print?

Colors on screen use light (RGB), while printed colors use ink (CMYK or spot colors). These systems are different. Your monitor's calibration, your printer's settings, and the paper type all affect the final print. This difference is why physical Pantone swatch books are essential; they show the actual ink on paper, bridging the gap between digital design and physical output, you know. It is a common challenge, but physical books help a lot.

Conclusion

Getting Pantone 300C to look just right, whether on a screen or in print, involves a good understanding of color systems and careful attention to detail. From the challenges of printing your own color charts from Illustrator to navigating software updates and ensuring compliance with Pantone standards, there are many aspects to consider. The shift to services like Pantone Connect, driven by how software manages color libraries, highlights the ongoing need for accurate digital and physical references. It is a journey of precision, in a way.

The importance of using physical Pantone books cannot be overstated for true color accuracy, especially when customers demand precise PMS matches for things like dimensional letters or race car decals. Understanding the difference between spot colors and CMYK approximations, and knowing how to troubleshoot common printing issues, are skills that make a big difference. It is all about making sure that vibrant blue always appears as it should, you know. You can learn more about color consistency on our site, and for more specific guidance on printing, link to this page printing tips for designers.

Detail Author:

- Name : Guiseppe Kuhic

- Username : vada.denesik

- Email : dennis12@cole.com

- Birthdate : 1982-10-03

- Address : 4453 Heaney Ramp Apt. 281 Runtefort, VA 72837-7745

- Phone : 415-988-0266

- Company : Bosco-Halvorson

- Job : Municipal Fire Fighting Supervisor

- Bio : Consequuntur in porro dolorem aut quas sed minus. Aperiam tempore fugit voluptatem. Optio placeat et sit itaque ipsum ut ipsa eaque. Quo rerum voluptas harum quam non odit quasi.

Socials

twitter:

- url : https://twitter.com/ned_official

- username : ned_official

- bio : Harum ea voluptates atque est. Consequatur ut debitis ut maiores officiis quo.

- followers : 6328

- following : 448

facebook:

- url : https://facebook.com/nschroeder

- username : nschroeder

- bio : Deserunt et et ipsa quibusdam odio.

- followers : 258

- following : 1204

tiktok:

- url : https://tiktok.com/@nschroeder

- username : nschroeder

- bio : Nihil aspernatur nihil saepe.

- followers : 5074

- following : 1750